General Care

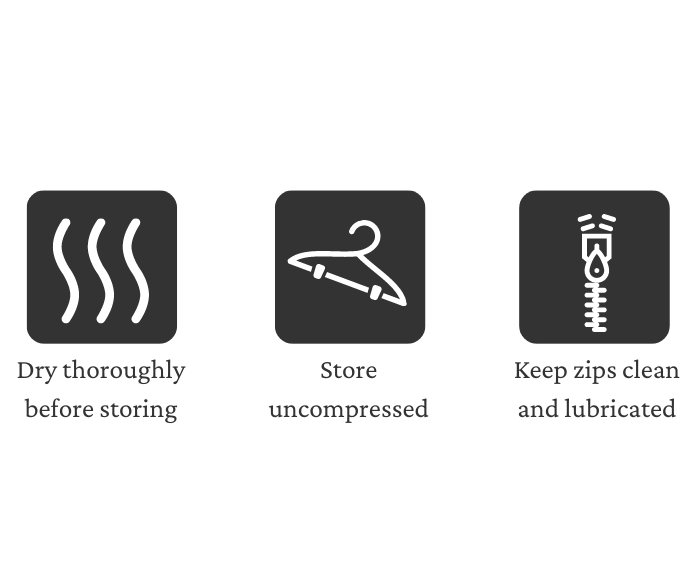

With care your insulated clothing, especially if filled with down, should last many years but all insulated clothing will last longer and perform better if cared for correctly. During use, especially on extended trips, air your clothing whenever practical and dry thoroughly before storing.

When not in use, store your insulated clothing uncompressed, either hung inside a wardrobe or loosely stuffed into a large storage sack or pillow case. If possible avoid storing inside its stuff-sack or pack pocket for long periods of time. Small stains and spillages can usually be cleaned with a damp soapy cloth but avoid washing insulated garments unless they really need it. Zips should be kept clean and regularly lubed.

How to Wash - Down Clothing

If you do not have immediate access to a tumble dryer or to strong sun and a breezy day, please do not attempt to wash a down insulated garment yourself.

Down clothing is more difficult than most clothing to wash, but the task can be managed at home. The difficult part is not actually the washing, but the drying. The washing cycle can be done in most large household washing machines but the process of drying, which can take several hours, requires a tumble dryer or a sunny and breezy day. Do not dry clean your down clothing.

If you have any doubt about carrying out the task yourself, or if your clothing contains a lot of down, then you should consider sending your clothing to a specialist down cleaning service.

The garment should ideally be washed using a specialist down cleaning product such asGrangers Down Wash,Nikwax Down Wash Direct,Storm Down Wash, orFibertec Down Wash Eco. If these aren’t available then soap flakes which can be purchased from a supermarket are also fine. Do not use detergent or fabric softener.

Before you begin, clean any detergent out of your washing machine: if you use the powder drawer, give it a thorough clean, pouring hot water down it to remove any residue. Finally, run a short rinse cycle with the machine empty to clear any remaining detergent.

Ensure all pockets are empty, drawcords under tension are released, velcro adjusters fastened, and all zips including pocket zips are done up fully. Read the care label. Despite the care label possibly suggesting your garment can only be hand-washed, provided you select the appropriate setting, it is ok to use a domestic washing machine.

Select a programme with a low to medium spin speed setting such as Delicates, Woollens or Handwash and with a temperature setting of 30°C. Avoid washing multiple garments at once. Rinse extremely thoroughly (at least twice).

When removing your garment from the machine, do so carefully, as the extra weight of any wet filling could damage internal stitching. Your garment may well look flat, empty and / or lumpy. At this stage don’t worry.

-

How to Wash an Insulated Waterproof Jacket

If you do not have immediate access to a tumble dryer, please do not attempt to wash an insulated waterproof garment yourself. The following advice assumes access to a tumble dryer.

The garment should ideally be washed using a specialist cleaning product such as Grangers Performance Wash. If these aren’t available then soap flakes which can be purchased from a supermarket are also fine. If your garment is extremely dirty then simple liquid detergent without fabric softeners can be used as a last resort, but only if other methods have not managed to clean your garment. Do not under any circumstances use fabric conditioner: it will likely ruin the fabric’s DWR and may cause lasting damage to the construction of the product.

Before you begin, clean any detergent out of your washing machine: if you use the powder drawer, give it a thorough clean, pouring hot water down it to remove any residue. Finally, run a short rinse cycle with the machine empty to clear any remaining detergent.

Ensure all pockets are empty, drawcords under tension are released, velcro adjusters fastened, and all zips including pocket zips and ventilation zips are done up fully.

Read the care label. Take note of the filling type (down or polyester).

Select the appropriate wash cycle on your machine - ideally this should be a programme with a low to medium spin speed setting such as Delicates, Woollens or Handwash and with a temperature setting of 30°C or 40°C . Avoid washing multiple garments at once. Rinse extremely thoroughly (at least twice).

When removing your garment from the machine, do so carefully, as the extra weight of any wet filling could damage internal stitching. If your insulated waterproof clothing is down-filled, the garment may well look flat, empty and / or lumpy. At this stage don’t worry. Your garment now needs to be dried extremely thoroughly. This should be done slowly, using a tumble dryer set to the lowest heat setting available. Selecting a higher temperature in the hope of drying more quickly could easily damage the fabrics and components of your garment.

If your waterproof jacket is down filled (and not synthetic / polyester), the drying process may take several hours, particularly for heavier items of clothing. During this time, periodically check the garment (remove from the tumble dryer) to ensure that it is not getting too hot. If your garment is down filled we also recommend massaging the filling between your hands at frequent intervals. It is important to start this process before the garment becomes too dry; doing so will help to tease apart any clumps and ensure that it regains its natural loft. This process can be aided by adding a couple of tennis balls or other small but firm items to the drum whilst drying.

Tumble-drying will at the same time help to reactivate any DWR (Durable Water Repellency) treatment on the outer fabric. This can also be achieved by carefully ironing the outer fabric on a warm setting, ensuring to place a thin cloth between the garment and the iron. Do not allow the iron to come into contact with any zips, gaskets or logos.

Finally all components such as cordlocks should be checked and zips thoroughly lubed. We recommend using a product such asGear Aid Zipper Lubricant,McNETT Zip Careor Zipper Stick. Alternatively natural products such as Beeswax can also be used. The garment can then be stored away as normal.

How to Dry - Down Clothing

Your garment now needs to be dried extremely thoroughly. This should be done using a tumble dryer set to the lowest heat setting available, or hanging outside on a reliably warm and sunny day. If using a tumble drier, selecting a higher temperature in the hope of drying more quickly could easily damage the fabrics and components of your garment.

The drying process may take several hours, particularly for heavier items of clothing. If using the tumble drier periodically check (remove from the tumble dryer) the garment to ensure that it is not getting too hot. During drying, occasionally tease apart any clumps of down with your hands to ensure that the filling regains its natural loft: any lumps will not dry properly and will make the jacket seem underfilled and flat. If using a tumble drier, drying can be aided by adding a couple of tennis balls or other small but firm items to the drum.

Once thoroughly dried, all components such as cordlocks should be checked and zips thoroughly lubed. We recommend using a product such as Gear Aid Zipper Lubricant, McNETT Zip Care or Zipper Stick. Alternatively natural products such as Beeswax can also be used. The garment can then be stored away as normal.

Minimising Down Leakage

The fabrics we use on our down garments are densely woven to ensure that fibre migration (down or fibres passing through them) is minimised. They may be ciréd under a hot roller to further increase their downproofness, or coated with micron-thick polymers to practically eliminate down migration. However, down barbs or barbules will occasionally find their way through a fabric or, more likely, through the seams.

Ranging in diameter from 20 to just 2 microns in diameter, it is practically impossible to stop down barbs and barbules penetrating sewn seams and fabrics altogether. Feather quills may also occasionally penetrate a fabric too: quills are rigid and sharp and, just like a needle, can poke through fabrics if given the correct force and orientation.

So, if you do notice the occasional fibre poking through, this isn’t a fault. Do not be tempted to pull the down out of the garment and make a tiny hole that little bit bigger. Instead, reach behind the fabric and gently pinch the down cluster and pull it back inside the bag.

How to Wash - Synthetic Clothing

Synthetic insulated clothing is easier to care for than down filled clothing especially when it comes to washing and drying, but even so it should be washed only when absolutely necessary.

The garment should ideally be washed using a specialist cleaning product such as Grangers Performance Wash, Nikwax Tech Wash, Fibertec Pro Wash, or Storm Clothing Wash. If these aren’t available then soap flakes which can be purchased from a supermarket are also fine, and failing that simple liquid detergent without fabric softeners can be used but is not something we officially recommend.

Before you begin, clean any detergent out of your washing machine: if you use the powder drawer, give it a thorough clean, pouring hot water down it to remove any residue. Finally, run a short rinse cycle with the machine empty to clear any remaining detergent.

Ensure all pockets are empty, drawcords under tension are released, velcro adjusters fastened, and all zips including pocket zips are done up fully.

Read the care label.

Select the appropriate wash cycle on your machine - ideally this should be a programme with a low spin speed setting such as Delicates, Woollens or Handwash and with a temperature setting of 30°C. Avoid washing multiple garments at once. Rinse thoroughly.

When removing your garment from the machine, do so carefully - especially for heavily insulated garments as the extra weight of any wet filling could damage internal stitching. Most lightweight synthetic garments are easily air dried but for heavier weight garments we recommend the use of a tumble dryer. This should be done slowly, using a tumble dryer set to the lowest heat setting available. Selecting a higher temperature in the hope of drying more quickly could easily damage the fabrics and components of your garment.

Once thoroughly dried, all components such as cordlocks should be checked and zips thoroughly lubed. We recommend using a product such as Gear Aid Zipper Lubricant, McNETT Zip Care or Zipper Stick. Alternatively natural products such as Beeswax can also be used.

Field Repairs - Down Clothing

Insulated jackets, especially those filled with down are by their very nature lightweight and as such the demands of climbing and mountaineering can cause damage usually in the form of snags and tears to even the most well designed product. Such damage is not covered by our warranty as this is deemed normal, if unfortunate, wear and tear. However, many of these faults can be repaired both ‘in the field’ and professionally.

-

Small Tears - Gaffa Tape / Duct Tape

Gaffa Tape or Duct tape applied over the immediate tear can work effectively for short-term fixes of insulated clothing. The outer fabric needs to be clean and dry. Any filling should be compressed flat before application. It’s unlikely to be a permanent solution.

-

Small to Medium Sized Tears - Tenacious Tape™ or Betrafol® Tape

Specialist repair tapes such as Tenacious Tape™ or Betrafol® Tape can be very effective at repairing small tears, but they do have a somewhat distinctive aesthetic. Please be aware however that such tapes, whilst extremely durable and often able to endure sustained use even at very low temperatures can leave residual marks which when taken off are near impossible to remove.

-

Leaking Quills/ Feather

Any stray feather or quill poking through seams or the fabric itself should be pushed back into the garment or pinched from the inside and pulled back in. Avoid the temptation to pull out - doing so will enlarge any tiny hole increasing the chances of it happening again.

-

Jammed or stiff Zip Pulls

Prevention is the best form of cure so regularly clean all zips using warm, soapy water. Do not force jammed zips. If washing and lubing a zip does not free a zip, carefully inspect the zip head for obvious signs of grit or dirt. If tooth or coil damage is visible then the zip puller has already had too much force exerted on it. Only a professional repair can solve this.

Professional Repair

Should you require a professional repair, many of the common problems which occur through use can be rectified and will ensure your insulated clothing continues to provide many more years of service. This includes partially or completely replacing zips, replacing or re-attaching drawcords, professionally patching fabric tears or nicks and repairing damaged baffles. Contact us for further information.

Field Repairs - Synthetic Clothing

Synthetically insulated clothing can take a bit of a beating. Seconding pitches with numb hands and abandon can cause holes or tears in clothing pretty quickly, and the general rough treatment of use in rain, snow and high winds causes wear on components. However, repairs are usually a little easier than with down garments.

For holes or tears, you can choose to repair with gaffa tape or duct tape (likely not a permanent solution), with Tenacious Tape or Betrafol (very durable but distinctive DIY aesthetic), or undergo a proper repair with sewing and/or heat bonding. Larger holes may need patches, and we can sometimes provide these. A proper repair of a synthetic jacket may barely be noticeable.

Constructional problems such as drawcord, zip or component faults may or may not be repairable depending on the makeup of the garment.

End of Life

Insulated clothing, especially that which is down filled, should last many years and whilst some components can wear out more quickly, the insulation itself should keep working almost indefinitely. Synthetic fillings will wear out and degrade over time. But if you think your clothing is nearing the end of its life please do everything you can to prolong it. Wear it until it falls apart. All insulated garments, even the simplest can involve many components and materials which are energy intensive to produce and one of the most effective ways of reducing their environmental impact is, as strange as it may seem for us to say, to make what you buy last as long as possible and not replace it needlessly.

Here's what you should do instead:

1)Revere it - Our products are made to be used. Learn to value the experience etched into the very fabric of your gear. Every nick, every mark is not just wear & tear but a story and a statement.

2) Revitalise it - Wash and maintain your garment when required and store appropriately. A flat and lifeless jacket can be brought back to life by washing. You can do this yourself or use the services of a professional down care company.

3) Repair it - Many minor faults that may seem terminal can actually be easily fixed. It may seem expensive but think about the cost not just of a new jacket but the bigger environmental cost to your consumption.

4) Relegate it - Just because your jacket can no longer cope with a trip to Patagonia does not mean that it isn't ‘good enough’ for a wide range of less severe uses. So consider relegating your insulated jacket to the jacket you reach for when walking the dog or occasional cold weather walks.

5) Reappropriate it - Use the garment for something it was not originally designed for but works perfectly for. Keep an old insulated jacket in your car in case of breakdowns or for fitting snow chains, use it for cold weather gardening or chopping logs.

6) Reassign it - Just because a jacket may not meet your needs any longer it may meet someone elses. Don’t use this as an excuse to not think about your own actions (!) - but there are numerous specialist charities who need outdoor clothing and many groups will gratefully receive donations of used gear, even if slightly damaged.

7) Reuse it - Synthetic Jackets can be cut down and their filling used in cushions etc or re-purposed for your dogs bed. Basically anything that requires something to be warm and soft can be made from pieces of your waterproof clothing. Avoid doing so with down-filling unless you like down clusters everywhere!

8) Recycle it - Recycling can save energy and resources that would otherwise be used in the manufacture of virgin materials or in the case of down, in the rearing of geese and ducks. The good news is that down insulation can now be effectively recycled via our Down Cycle initiative. Some synthetic fillings can also be recycled but it is not currently common practice. The materials found within the garment itself are less easily recycled but some can be, typically being re-used in non-woven low-grade insulation for ducting etc. That’s why we’d ask that you try to do everything you can to keep your insulated clothing in use for longer.